Early on, the aerospace industry was one of the first to embrace 3D printing services and adapt them in order to keep up with developments that occurred during the 1980s. 3D printing offers flexibility for the future, but also enables the kind of technical production innovations that should ensure that the aerospace industry continues to thrive.

The impact of additive manufacturing on the aerospace industry can be seen in several important areas:

- In production of a number of instruments, jigs, gauges and templates it is also used to bring down costs

- For training purposes, 3D printing provides temporary parts that act as surrogates

- For the production of metal brackets which operate as structural components in an aircraft

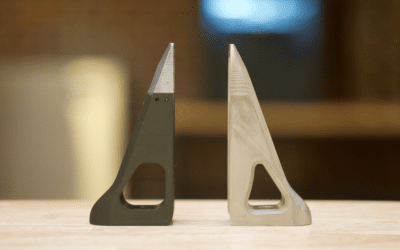

- Prototypes have become more and more 3D printed, which enables designers to adjust shape and size of the final parts

- Interior aircraft components, such as cockpit dashboards and door handles, are manufactured by 3D printing services

- This technology has a growing role to play in producing lighter, more effective parts for engines and turbines

The Production Benefits of 3D Printing

Normally, aircraft parts are manufactured in limited periods of time, and as a result, high costs have been built up in the past. The production cost has been lowered and new efficiencies are being introduced, however, by the use of additive manufacturing. It allows manufacturers to produce short runs of complex, and very large parts for aircrafts. In addition, a number of these vital components will be lighter and more resilient in comparison to the traditionally produced parts.

Reducing Aircraft Weight with 3D Components

In order to reduce air transport’s ecological impact, weight plays an essential role. 3D printed parts help reduce the air drag of an aircraft and lower fuel consumption by reducing its weight. The aircraft’s weight will increase drag at a given speed because the wing has to generate sufficient lift from that point on. However, cruise altitude is where the biggest impact weight lies.

Since air density is required for lift, heavier aircraft weight will result in a lowering of the cruise altitude. The greater the air density, the more impact draft will have. Consequently, there will be an increase in fuel consumption. A reduction of aircraft weight can be achieved by the use of carbon fiber materials and shape memory alloys, allowing for more efficient construction.

Eliminating Expensive Tooling Changes

Different parts will have to be prepared using various tooling, all of which increases costs and time for the production of aircraft components in conventional manufacturing processes. 3D printing offers aerospace manufacturers the opportunity to implement what is effectively tool-less manufacturing. This allows them to produce modified components or replacements on demand and does not require a large amount of component stock.

Complex and slim structures can be produced using 3D printing, which have a high degree of stability. Multiple smaller components can also be combined into a single component, thanks to 3D printing. This helps to simplify the production process so that it is more efficient and reduces waste.

Aerospace Design, Production and 3D Printing

The whole process of making planes is affected and changed as a result of 3D printing. Conceptual modeling, including sophisticated scale models, are part of 3D at the design stage. In the aerospace sector, there has been a widespread use of 3D technology to create prototypes, and the range of options may be full scale enclosures or concept models.

3D printing is revolutionizing the aerospace industry by allowing component production to be carried out quickly and on demand, thereby reducing the costs of production while improving aircraft performance. As a flexible manufacturing solution for aerospace, 3D printing also provides increased capacity for customization in production, for both interiors and functional parts.

Preparing Aerospace for the Future with 3D Printing

Like many other sectors, aerospace has been subject to a number of future uncertainties, including the global supply chain strain and the impact of environmental regulations. It must have both the ability to react quickly and be responsive to change, so that it can maintain its growth. In how the aerospace sector embraces its future, 3D printing will play an important role. The use of 3D printing services or technologies in the current workflows at a crucial stage can contribute to faster processing and provide increased clarity for designers and aircraft manufacturers on new innovations that could improve their performance.

From research and development to ongoing aircraft improvements, the ability to improve efficiency while reducing costs is made possible by 3D printing. Each component is required to have an airworthiness certificate in aircraft production, and as the reliability and durability of 3D printed parts have been demonstrated in practice, it is becoming increasingly evident that 3D printing will become an industry standard in aerospace.

Interested in learning more? Watch our recent webinar about additive manufacturing in aerospace and learn how today’s advanced additive manufacturing technologies contribute towards innovative improvements in the aerospace industry.