Finding a solution was much easier when disruptive events affected supply chains before the 2020 Coronavirus pandemic. Finding a new supplier for production line replacement parts wasn’t an impossible task because multiple, global-scale disruptions weren’t typical, so they didn’t happen all at once. Therefore, traditional procurement techniques and risk management frameworks could theoretically achieve supply chain “resilience” back then.

Today, supply chain disruptions continue to happen with steadily higher frequencies and less predictable magnitudes. When a single disruptive event is combined with the need for even a simple replacement part, manufacturers relying on antiquated traditional supply chain management strategies are easily forced to extend production line downtime.

How then can manufacturers ensure uptime on their factory floors in today’s world of precarious availability? While conventional just-in-time (JIT) supply chain management models alone are too taut and brittle to succeed through constant uncertainty, today’s advanced additive manufacturing technologies have evolved to add resilience through greater flexibility.

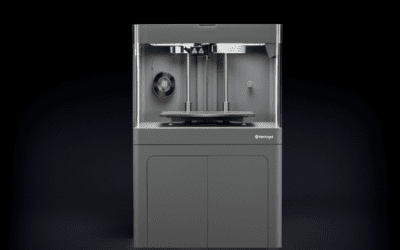

Today’s industrial 3D printers can give supply chain operators a potent new autonomy by enabling production capabilities right where they are needed for everything that keeps factory floors operating, including high-performance replacement parts, production tooling and fixtures, MRO parts, or ergonomic equipment.

Preparing for Today’s Supply Chain Environment

Although manufacturers have traditionally dealt with supply chain disruptions through thorough risk mitigation plans, the theoretical “resilience” of these supply chains has been based on the idea that their effects can be predictably planned for and dealt with.

Factors behind these large-scale disruptions tend to unfold behind the scenes, but when considering what specific factors and variables ultimately influence and limit availability of large portions of the world’s supply chains, the question arises as to whether manufacturers can accurately track, predict, and plan around large-scale geopolitical shifts far beyond their control. They are undetectable until they have already had a catastrophic effect, blindsiding supply chains and upending them.

Many different factors and overlapping dependencies make up the complexity of supply chains. A disruptive event at any one point in these interconnected webs can have unpredicted cascading effects that eventually cause a number of other supply chains to fail completely.

The JIT supply chain model has been susceptible to these disruptions in the new uncertain status quo. JIT depends on precise supplier and manufacturer communication as well as minimal inventories. Solutions are not as simple as having straightforward contingency plans when the effects of disruptions cascade across entire supplier ecosystems. These factory floors are vulnerable to prolonged periods of expensive downtime if there are no substantial inventories to fall back on or quick and flexible production available when needed. An entire production line can be stopped while waiting for a single replacement part, which can take months to obtain.

Building Supply Chain Resilience Today

It is not a foolproof solution to continually review supply networks. The continuous re-planning of intricate, interconnected manufacturing supply chains is not only a time- and resource-intensive endeavor due to the high frequency of disruptive events, but it is also an ineffective long-term strategy.

Therefore, manufacturers seeking a more dependable buffer against disruptions to factory floor operations must change the way they approach supply chains to one that is more flexible and agile. What then can manufacturers do to obtain essential replacement parts without endangering production uptime with uncertainty and unnecessarily long lead times?

Growing numbers of businesses have introduced industrial 3D printing to their factory floors to improve operations as federal initiatives like AM Forward highlight the transformational value of cutting-edge technologies like additive manufacturing in supply chain management.

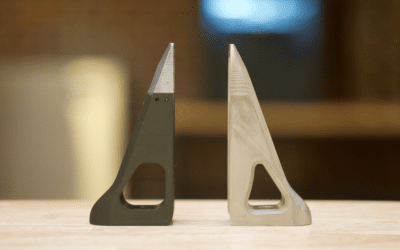

Using a variety of industrial metals and metal-strength composites, modern additive manufacturing technology can create production-quality parts in a short amount of time. When issues arise, technicians can quickly and easily print the solutions they require right away on factory floors — tooling and fixtures, MRO equipment, ergonomic solutions, or any other essential production components — without requiring a lot of downtime.

In the end, using 3D printing allows you to have flexible supply chains without having to increase your physical inventory levels. Instead of maintaining an inventory of spare parts, parts can be stored in the cloud as digital inventory, which can then be printed out into a physical part in a matter of hours.

The ability to design and print a solution for any problem that arises gives factory floors autonomy and control in today’s world of unstable supply chains — rather than having to wait weeks or even months for a crucial component to arrive. Today’s supply chains are marked by far higher levels of risk and uncertainty, which are almost constant.

How Additive Manufacturing Solves Supply Chain Strain

Manufacturing companies benefit from supply chain resilience in several ways when they use industrial 3D printing for point-of-need production:

Reduced reliance on conventional suppliers: By allowing manufacturers to produce parts and components internally, AM helps them cut back on their reliance on third parties. Employees on the factory floor are given the authority to take matters into their own hands by designing and 3D printing a solution if there are disruptions to the current supply chains.

Production on demand: With the help of 3D printing, manufacturers can create goods as needed, doing away with the need for large inventories and lowering the likelihood of having too much inventory.

Digital inventory: This enables the cloud-based storage of parts as 3D design files that can be quickly transformed into physical objects. Due to their flexibility, manufacturers can react quickly to changes in demand or unanticipated supply chain disruptions.

Large industrial manufacturers are using secure digital inventories to store approved, current parts that can be quickly found and printed wherever they are needed thanks to today’s more advanced 3D printing software platforms. Their transfer is permitted without running the risk of design inconsistencies or a breach of intellectual property thanks to a safe, shared repository of up-to-date part files.

Localization of production: 3D printing enables businesses to locate production facilities near their clients. Localization lowers lead times, transportation costs, and lessens the possibility of long-distance shipping-related disruptions.

Access to spare parts: 3D printing can help with the problem of spare parts availability, particularly for older or discontinued parts. By using 3D printing, manufacturers can created the. necessary parts on-demand, minimizing any downtime on the factory floor, as opposed to depending on the availability of spare parts from suppliers and working with their schedules.

Networks of distributed manufacturing: 3D printing allows various facilities to cooperate and share their production resources. Production can be moved to other facilities in the network in the event of a disruption in one location, guaranteeing continuity and minimizing the effects of supply chain disruptions.

Interested in learning more? Watch our webinar about maximizing uptime in today’s supply chain environment. Click below to watch the on-demand recording: