3D printing adds tremendous value to supply chains and opens up a wide range of production opportunities in the automotive industry. The technology is becoming more workable and cost-effective as companies bring additive manufacturing to the factory floor to support processes. New, durable materials are opening up new ways to create high-precision, high-functionality 3D prints that stand in for finished parts and provide mass customization options and high performance. But that’s only the start.

From design to final parts, the opportunities for additive manufacturing in the automotive industry are endless. Read on to learn about popular 3D printing applications in automotive manufacturing.

Rapid Prototyping

In the automotive industry, prototyping has traditionally been one of the top 3D printing applications. Rapid prototyping has come to be known as 3D printing’s “gold standard” due to the speed at which 3D printing can be used for prototyping.

In the past, prototyping was costly and time-consuming since products go through numerous iterations. Prototypes that are highly functional, representative, and convincing can be made in a day with 3D printing for a lot less money than with conventional manufacturing techniques. With the help of 3D printers, engineering and design teams can strengthen their overall product development workflows by bringing the technology in-house and increasing iteration cycles and the time between idea and final product.

Automotive designers can rapidly create a 3D printed prototype of a physical component or assembly, ranging from an interior component to a dashboard or a scale model of a complete vehicle. Rapid prototyping allows companies to transform ideas into compelling proof-of-concepts. These concepts can be further refined to high-quality prototypes that accurately reflect the final product, leading to a series of validation steps that ultimately culminate in mass production.

Reverse Engineering

Reverse engineering has found a powerful ally in 3D printing, which offers benefits like cost and time savings. The geometry of a part can be rapidly captured by 3D scanning technology, which allows engineers to create a digital model and begin printing a replica with the required material properties. By doing away with the necessity for laborious manual measurements and design iterations, this finally speeds up the reverse engineering process.

Conventional reverse engineering techniques frequently entail laborious and time-consuming manual measurements, component disassembly, and substantial design work. Measurement and data collection time are greatly decreased with 3D printing when the part’s geometry is first captured by scanning. With computer-aided design (CAD) software, the digital model can be optimized and changed after it has been acquired.

Manufacturers have the capacity to complete the process internally, saving money on both transportation and outsourcing fees, as opposed to contracting out work to specialized facilities, which can be costly. Furthermore, complicated geometries can be produced using 3D printing’s flexibility without the need for expensive molds or tooling.

Manufacturing Aids

Manufacturing aids are required during manufacturing and assembly in order to produce high-quality parts. Even though injection molds, jigs, and fixtures aren’t final products or prototypes, they are nevertheless an essential part of the manufacturing process.

Automotive companies can now produce manufacturing aids at a fraction of the cost previously thought possible thanks to 3D printing technologies like FDM and SLS, which significantly boost factory floor efficiency. Additionally, manufacturing aids can be customized for enhanced functionality at a price much less than with traditional techniques.

Here are some examples of 3D printing manufacturing aids:

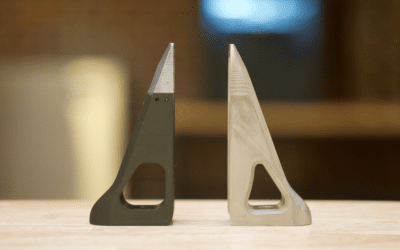

- Jigs and fixtures are specially designed instruments used in the manufacturing process to hold and position parts. This increases productivity and decreases downtime by enabling manufacturers to produce these tools quickly, precisely, and in a range of shapes thanks to 3D printing.

- Molds can be used for casting and injection molding after being 3D printed. This makes it feasible for manufacturers to produce intricate internal structures and geometries that would be challenging, if not impossible, to accomplish using conventional manufacturing techniques.

- Inspection and measurement tools can be precisely and specifically 3D printed and customized to make measurement and inspection tools like micrometers, gauge blocks, and custom-made gauges.

End-use Parts

The difficulties associated with locating and producing replacement parts are nothing new to the automotive sector. The demand for replacement components is often greater than what traditional manufacturing processes can handle due to the rapid advancements in technology. But the introduction of 3D printing has brought about a revolutionary solution that makes producing replacement parts and aftermarket components more effective and affordable.

The conventional method of making automobiles is expensive and complicated. It usually involves assembly lines, molding, and tooling, all of which demand significant time and financial commitments. Engineers can lower overall production costs and do away with the need for expensive tooling by utilizing additive technology. It is a desirable alternative for manufacturing replacement parts and aftermarket components due to its cost-effectiveness. Additive technology can be used to manufacture a wide range of vehicle components, from interior trim pieces to engine parts.

It can take a lot of time and money to source rare or discontinued parts using traditional manufacturing methods. But with additive manufacturing, spare parts can now be produced as needed, doing away with the need for huge inventories. This feature offers manufacturers and car owners an affordable solution while also saving time.

Down the Road

Given that complete cars are being produced using 3D printing, including sporty electric cars, utility concept cars, and cars made especially to support scientific research, you could argue that the future has already arrived. Later on in the journey? You won’t be shocked to see mass-produced, fully 3D printed automobiles on the market.

Interested in learning more about the benefits of 3D printing in automotive? Register for our upcoming webinar!