Football season is back and better than ever with innovative 3D technology safety features for player gear and equipment. NFL players receive new gear at the beginning of every season, and with one of the biggest concerns in football being head injuries due to the high rate of concussions and the potential for CTE (Chronic Traumatic Encephalopathy), the NFL is constantly researching new innovative methods to advance and improve the safety of football helmets for players. Now, while the risk of injury that comes with playing such a grueling sport is undeniable, customized protection that is unique to each player or position has proven to be a valuable solution for the sport, one made possible by 3D printing and scanning.

What role does 3D technology play?

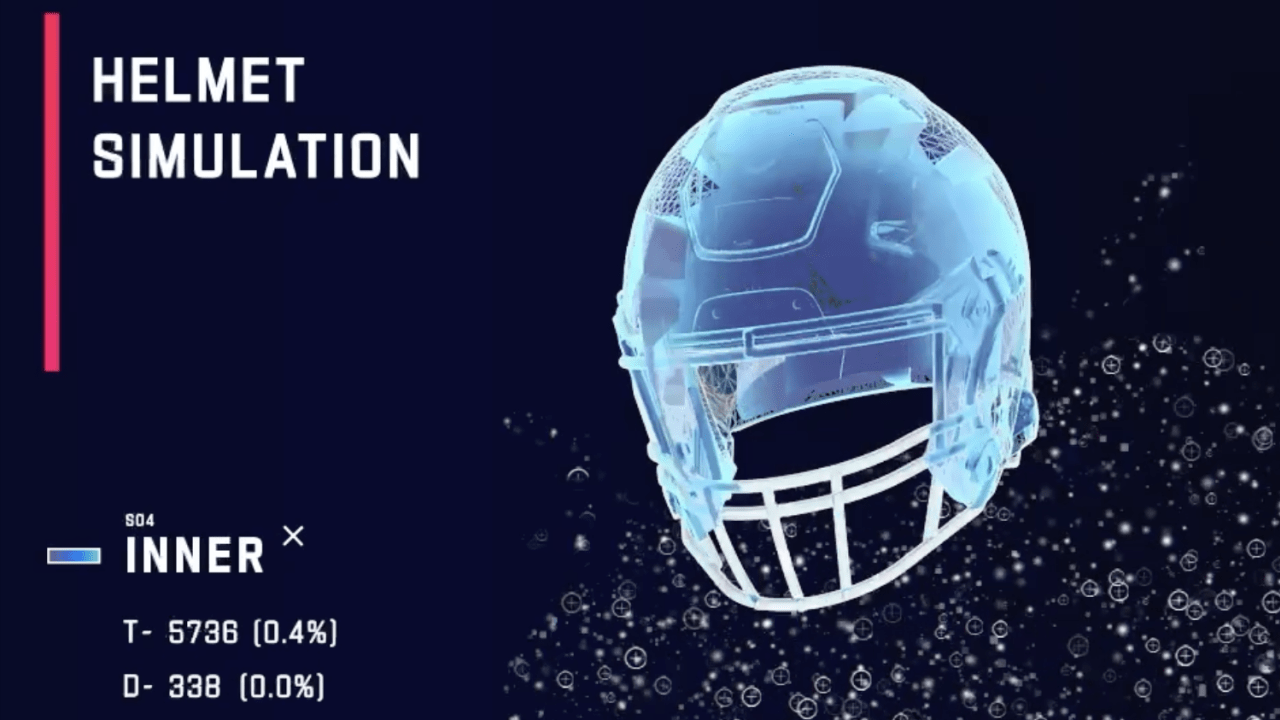

On behalf of the NFL and the NFLPA, biomechanical engineers annually perform extensive research and testing on helmet models, even going as far as recreating real-time playing scenarios to gather intel and determine which helmet models can withstand and reduce the effects of severe impact. Additionally, the NFL hosts innovation challenges such as the NFL Helmet Challenge and provides funding for innovators, manufacturers, and small businesses to have the opportunity to design new and improved helmets.

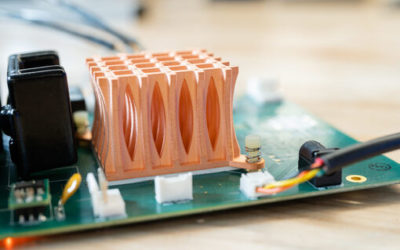

Both the NFL and some NCAA teams have adopted 3D technology to gain even further insight into protective football gear and equipment. Each position in football has its own unique safety characteristics, and leagues are now utilizing position-specific and player-specific helmets that can be customized through the use of both 3D scanning and 3D printing. 3D scanning is used to scan the surface of a player’s head to build a helmet that matches the fit of the head, and the helmet can then be 3D printed with the exact specifications determined for that player.

Has 3D technology proven effective?

The rate of improvement for helmet models is nine times faster since the start of the NFL annual testing program in 2015, and 99% of players are wearing top-performing helmets for the third consecutive season. This year, there are now more than 20 top-performing helmets for players to choose from, with five of the six new models tested ranked in the top-performing group.

With the help of 3D scanning and 3D printing, close to 200 players have upgraded to better performing helmets for the 2022 season than what they were wearing just last season. These better performing helmets have contributed to a 25% reduction in concussions in each of the last four seasons, and last season, concussions were at their lowest number ever.