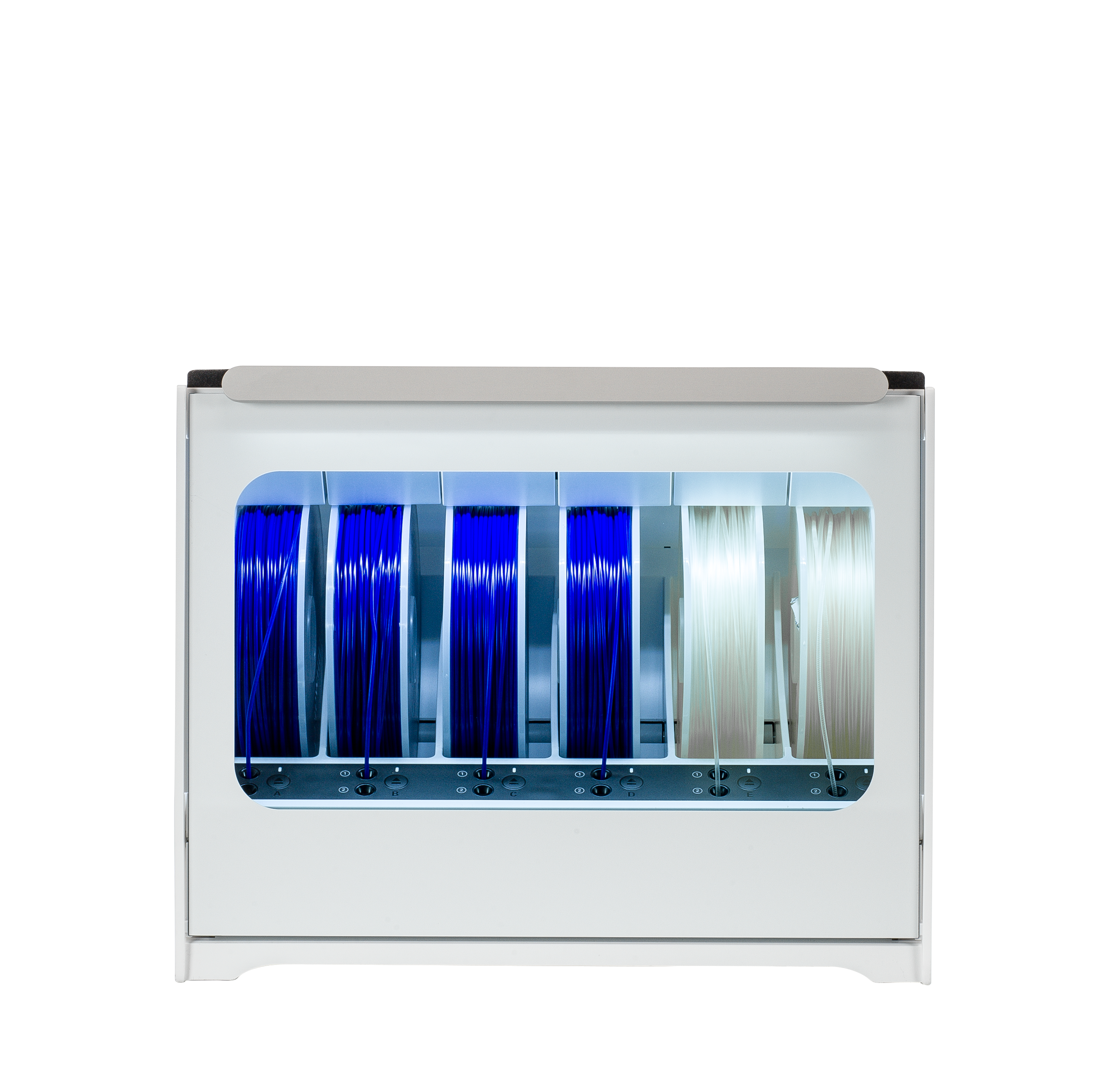

UltiMaker Material Station

All-the-time Productivity

The UltiMaker Material Station redefines material handling. No more DIY dry boxes, less time spent operating the printer. Integrated composite-ready filament management solution for the UltiMaker S7 and UltiMaker S5 3D printers, providing humidity-controlled storage with automated detection and switching for all UltiMaker filament, and support for additional third-party filaments being added regularly.

FREE STANDARD SHIPPING

$3,799.00

Available on backorder

Product Details

Key Features:

- Fast and easy loading: Front-facing bay for up to six materials reduces loading time to a few seconds

- Uninterrupted printing: Sensors detect when one material spool ends and automatically loads the next

- Humidity control: Intelligent atmospheric management keeps relative humidity below 40%

- Easy setup and monitoring: NFC material auto-recognition and seamless integration with UltiMaker software

- Composite materials compatible: Print parts with high strength and unique properties

- Limitless configurations: Keep your most-used materials ready to print when you need

Productivity to Power your Business

The UltiMaker Material Station redefines material handling – to unlock truly 24/7 production. Load up to six material spools inside the humidity-controlled chamber and smart features take care of the rest – composite ready feeder wheels, filament sensors, and automatic switching when a material runs out. Now you can achieve increased productivity and higher-quality production.

Flexible Material Handling

With the UltiMaker Material Station you can load and eject material from the front – even while another spool is printing. Simply place the material in a bay and insert the filament in extruder hole 1 or 2, then press the eject button when you want to remove it.

Optimized Settings per Material

UltiMaker Cura software now includes tested Air Manager fan settings per material, while UltiMaker Connect integrates seamlessly with the Material Station for optimized print job distribution. Whatever material you choose, benefit from improved print results, optimal air filtration, and efficient queuing – all with zero hassle.

Continuous Printing

The UltiMaker Material Station has been tested again and again to ensure its custom-designed filament prefeeders switch without fail. Load up to six materials and let the seamless material switching take over. It really is the end of those end-of-spool worries.

Reduced Operator Time

The UltiMaker Material Station reduces the risk of human error in material handling and storage. Its bays secure each filament spool so it can’t jump off. Ejected filament always retracts with a clean, sharp tip. And moisture-sensitive filament can be safely left in the humidity-controlled chamber.

Download Material Station Spec Sheet Now