It’s here! Introducing the newest addition to UltiMaker’s line of S-series 3D printers: The UltiMaker S7. Over 25,000 customers innovate with the UltiMaker S5 every day, making this award-winning machine one of the market’s best-loved professional 3D printers. The new UltiMaker S7 takes this 3D printing experience to the next level.

UltiMaker took everything our customers love about the award-winning S5… And made it even better. The UltiMaker S7 is packed full of our latest technology, making it easier than ever to reliably produce high-quality parts and models.

Print Removal Speeds to Flex About

The flexible steel build plate allows easy, toolless removal of 3D printed parts, making it possible to reset the UltiMaker S7 in a fraction of the time it normally takes. 25 magnets and 4 pins securely hold the plate in perfect alignment, allowing for one-handed operation. A sensor prevents a print from starting without the build plate present. And the flex plate’s PEI coating reduces the need for glue or build plate adhesion structures for some materials.

Print Monitoring in HD

Checking on your print remotely via UltiMaker Digital Factory never looked better. The new 1080p camera in the UltiMaker S7 is mounted higher to give a better view of the first layers. A continuous video feed update is coming later in 2023.

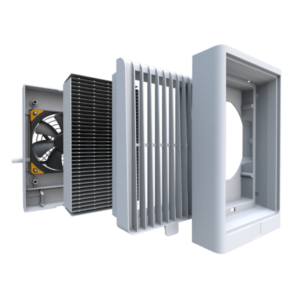

Easy Printing. Easy Breathing

The integrated Air Manager quietly filters the exhaust from every print on the UltiMaker S7. This process has been independently tested to remove up to 95% of ultrafine particles from every print.* It also fully encloses the build chamber. This and the single glass door leave fewer gaps to increase internal temperature stability and print quality, while giving you the freedom to place the printer anywhere – even next to open windows or HVAC systems.

*Tested by Fraunhofer WKI. Only including UltiMaker materials.

More Materials = More Applications

When you can simply click and print with over 280 materials, the potential for 3D printing applications becomes limitless. These material profiles (including engineering, composite, and recycled filaments) have been tested for thousands of hours by their manufacturers and users in the field.

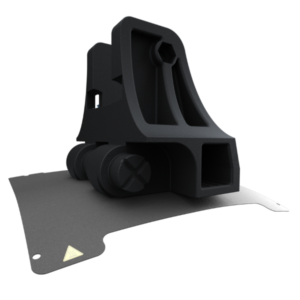

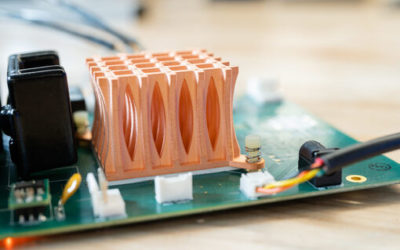

Probing Makes Perfect

3D prints succeed or fail because of their first layer. The new inductive sensor on the UltiMaker S7 more detects tiny variations in the build plate’s topography with less noise, increasing accuracy. Bed tilt is calibrated in the factory and automatically maintained, removing the need for thumbscrews and the chance of user error. Together these allow you to start a print and walk away – more confident than ever in a perfect first layer. Faster, touchless probing is coming Spring 2023.

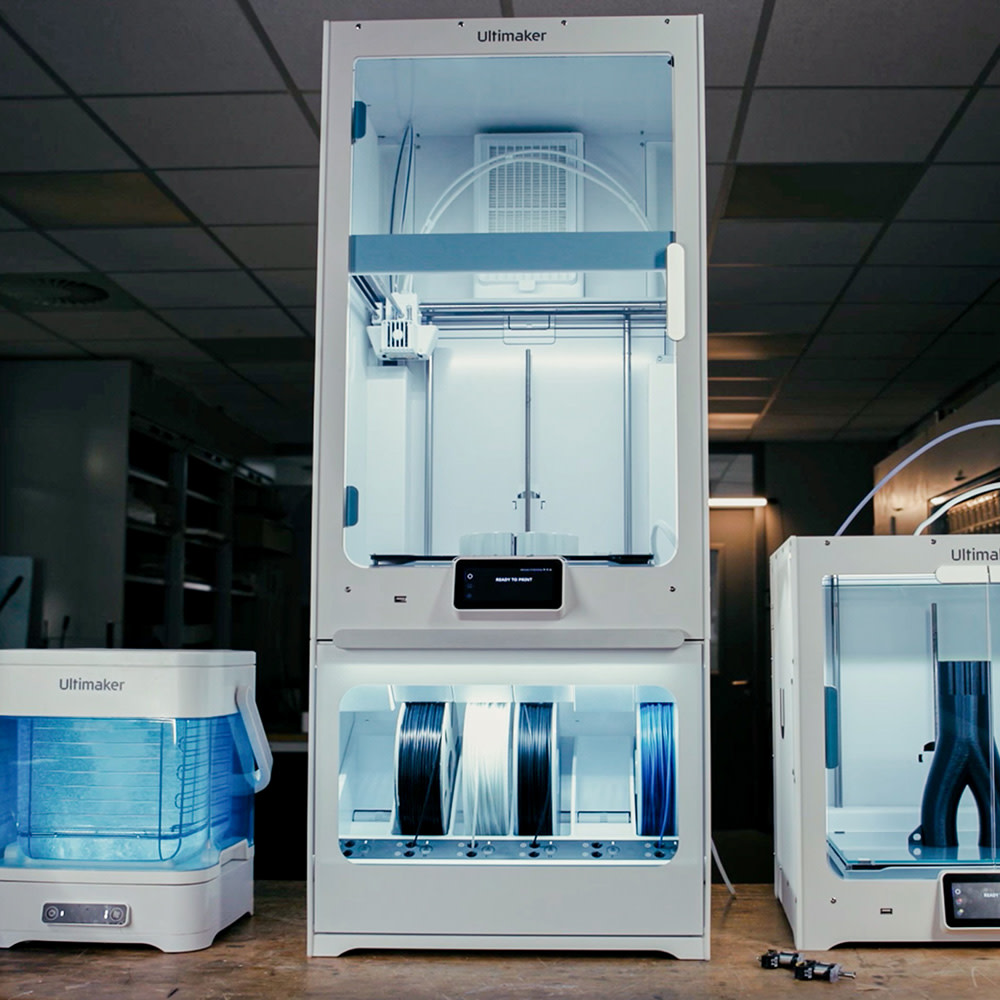

Complete the Bundle

The UltiMaker S7 Pro Bundle adds the Material Station to our newest S series 3D printer, transforming it into a manufacturing powerhouse. This one-of-a-kind upgrade further simplifies the 3D printing worklow with automatic switching of up to 6 spools. And constant humidity control ensures material is delivered in perfect condition for high-quality 3D prints.

The Material Station brings to the UltiMaker S7 high-quality 3D printed parts and models at maximum output. Its huge capacity and humidity-controlled material handling increases print success rate, print quality, and uptime to unlock 24/7 reliable production – while minimizing human error, print job time, and operator time.

How to Order the UltiMaker S7

The UltiMaker S7 and UltiMaker S7 Pro Bundle are both available for purchase in our store. If you would like to speak directly to a 3DOLOGiE representative, you may request a quote below.